It was just a matter of time, right? What I am talking about is the fact that 3D printing brought the only thing we haven’t seen yet, a 3D printer which prints itself. It’s almost inception-like when you think about it. On top of that, it makes the whole chicken and the egg thing come to mind as well. So what really existed first, the 3D printer or the 3D printer it printed? This DIY 3D printer project has turned a lot of heads and, as I said, it was only a matter of time before it happened.

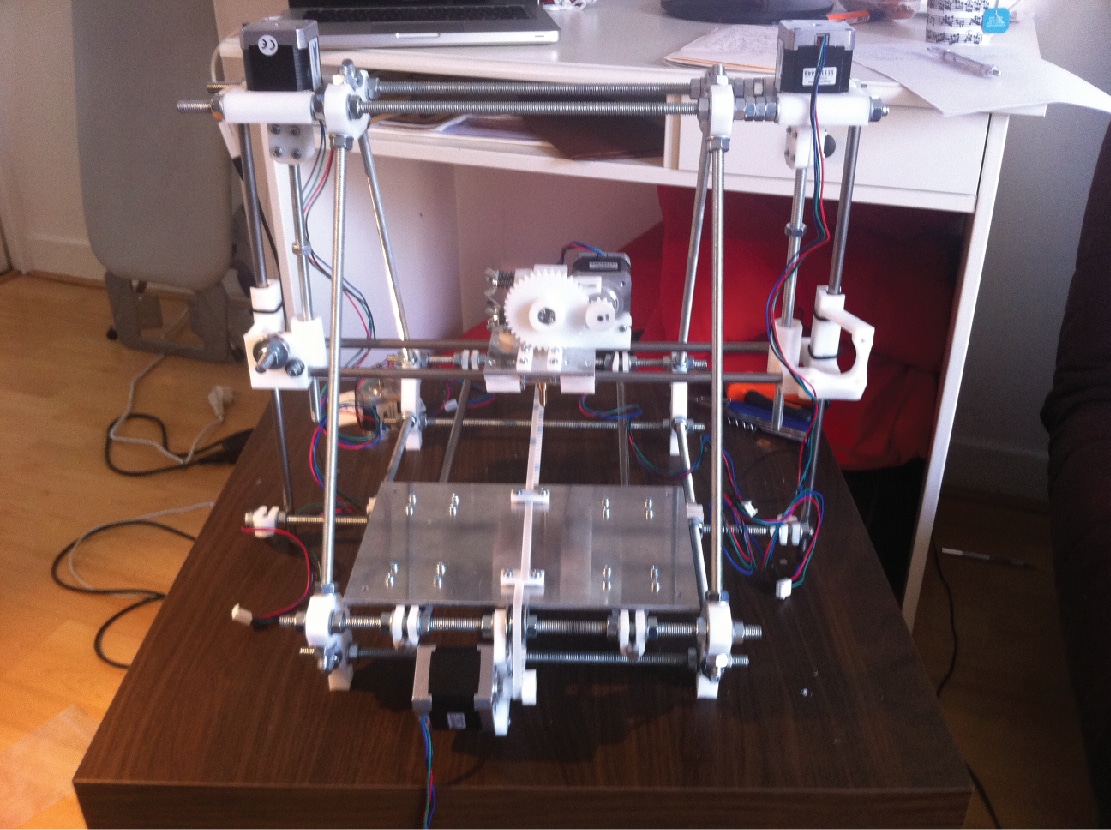

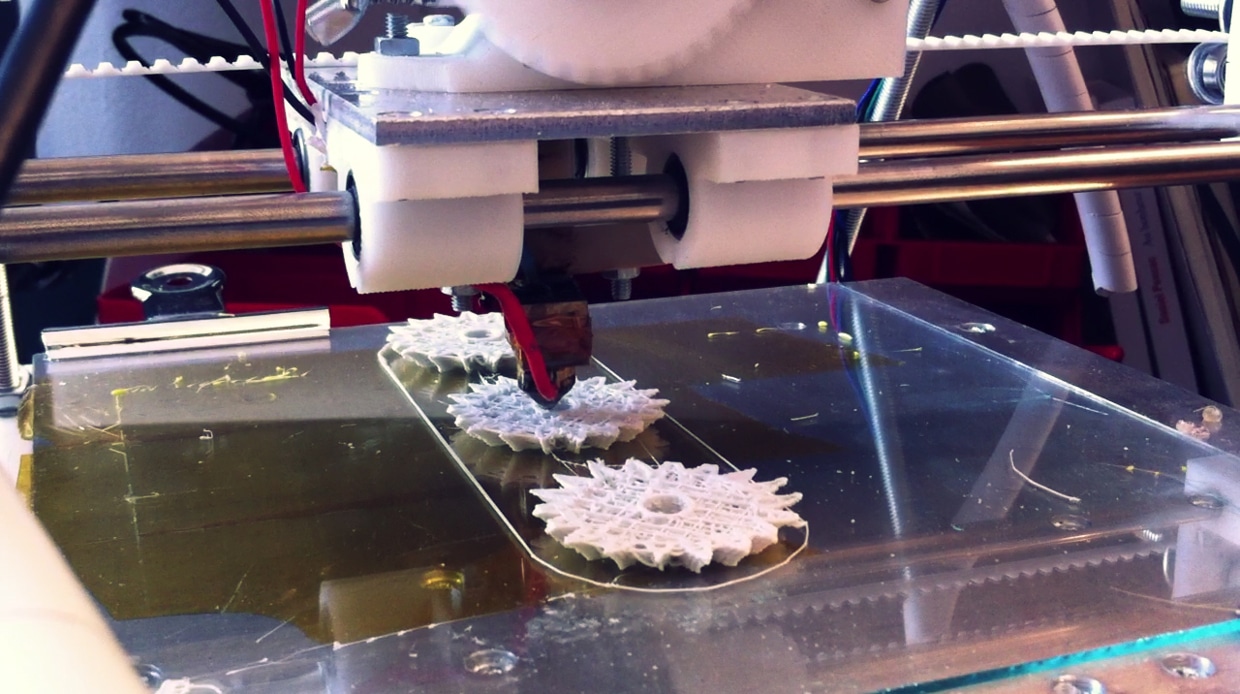

In the beginning, I too had trouble finding the start of it all. I mean, how does a DIY 3D printer print itself? It’s not quite that complicated. The project itself is far less complex than any kind of inception-like conspiracies we can come up with. The project is simply a DIY 3D printer that initially comes in a box, which is assembled and then used to print parts for an additional DIY 3D printer, basically.

This makes the whole “buy on the Internet, print immediately” business plan a super optimized endeavor. All you will ever need is to buy one initial DIY 3D printer, and then from that day forward you will only have to buy parts on the Internet to constantly upgrade or build a new one. How’s that for optimization? The idea is brought to reality by designer Pierre Paslier.

Pierre was introduced to Ardiuno and G Code machining and then created a rapid prototyping system that uses Fused Filament Fabrication technology to print 3D objects. The result is a 3D printer that can print a new 3D printer based off of standalone parts downloaded from the Internet. The 3D printing industry is rocketing to success, and this idea is going to make the whole endeavor a business we have previously not seen. Before long, we will all have a DIY 3D printer at home that we will print all our online purchases on – everything from clothes to food. The future of 3D printing is definitely here!

COMMENTS