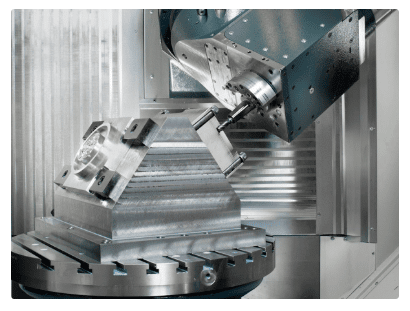

Even something as basic as creating a prototype is made easier by 3D printing. Using automation technology the process makes it more precise than it has ever been in the past. The first step in prototype creation is the acquisition of 5-axis CNC machining.

The machine streamlines the creation process. It has the ability to enable parts that have geometries complex enough to make the prototypes functional. Prototype production runs extra efficient because not as many machines are needed to complete the process.

Mass production of almost anything is among the most reliable manufacturing methods. It also cuts down on the cost of necessary labor. Each machine has a G code that results in the best possible automated production.

Manufacturing products on demand is necessary in today’s world. It helps to have CNC machining as it ensures the highest precision levels. When creating items such as prosthetics, this is crucial to the outcome. Prosthetics need to be made the exact same way each time.

No matter what pattern needs to be produced over and over, these machines will get the job done every time. There is a huge demand for identical prototypes and mass production is the best way to meet that demand. And when it comes time to print a new pattern, doing so couldn’t be easier.

In most cases, the creation of an initial prototype is a time for experimentation. This machine makes it possible to create one prototype using several different kinds of material. That allows one to determine which material works best for the prototype in question.

Using a CNC machining service, prototypes can be created using various kinds of coating. Being able to choose from numerous finishing processes gives the designers more control over the final product. These machines can create prototypes using mission or steel polishing, and aluminum anodizing.

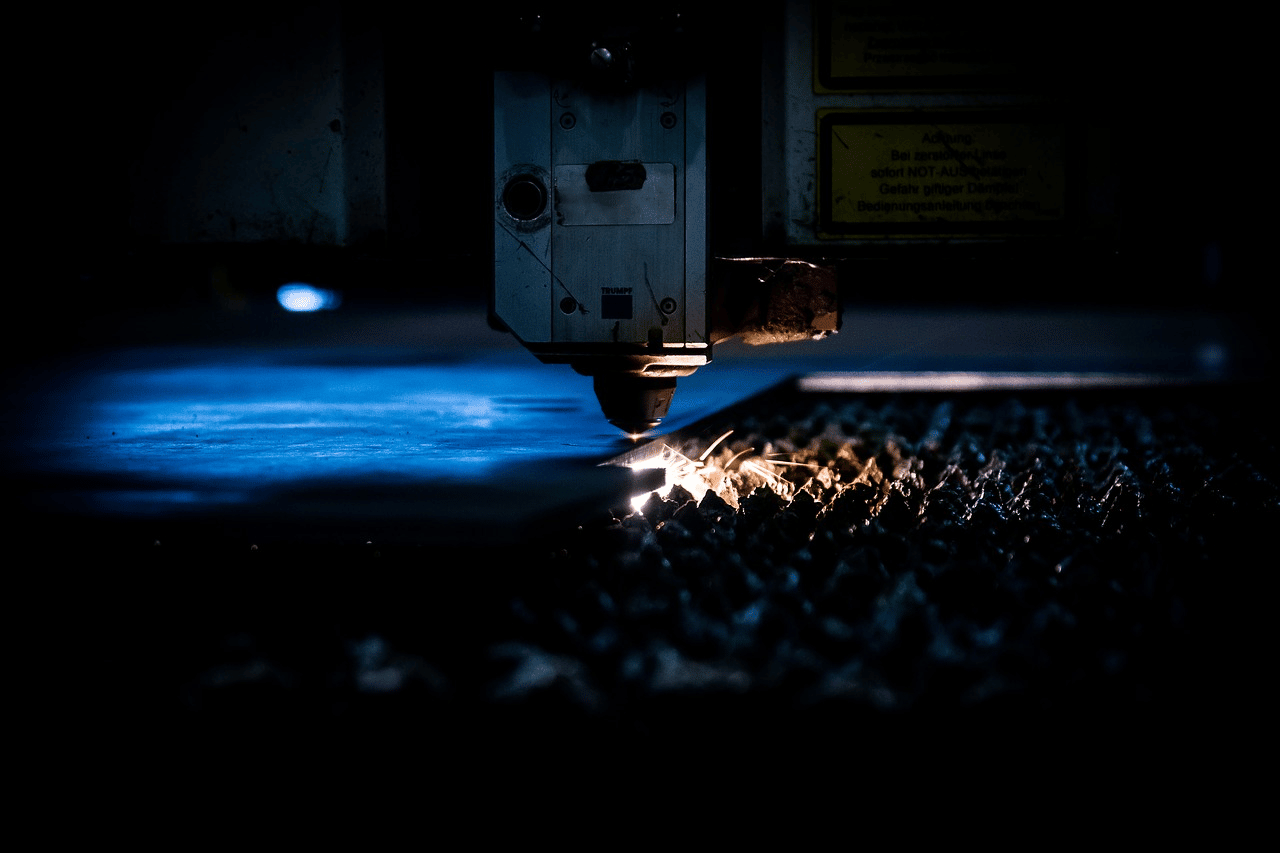

The process of creating anything with a CNC machine is enhanced by the use of cutting tools. No matter what shape the product being formed takes on, a CNC machine has the tools to manage it. Changing the tools used is as easy as hitting a button.

This includes the use of steel toolings to perform die casting and create plastic molds. Depending on how complex this particular task is, it can take multiple weeks to complete. The completion of a prototype often requires the time-consuming use of silicone molds and this can add even more days onto the process.

The creation of complex prototype parts for mass production generally requires the use of plastic and silicone molds. A CNC machine ensures that every mold turns out as smooth as possible. Obtaining these types of services is not difficult to do.

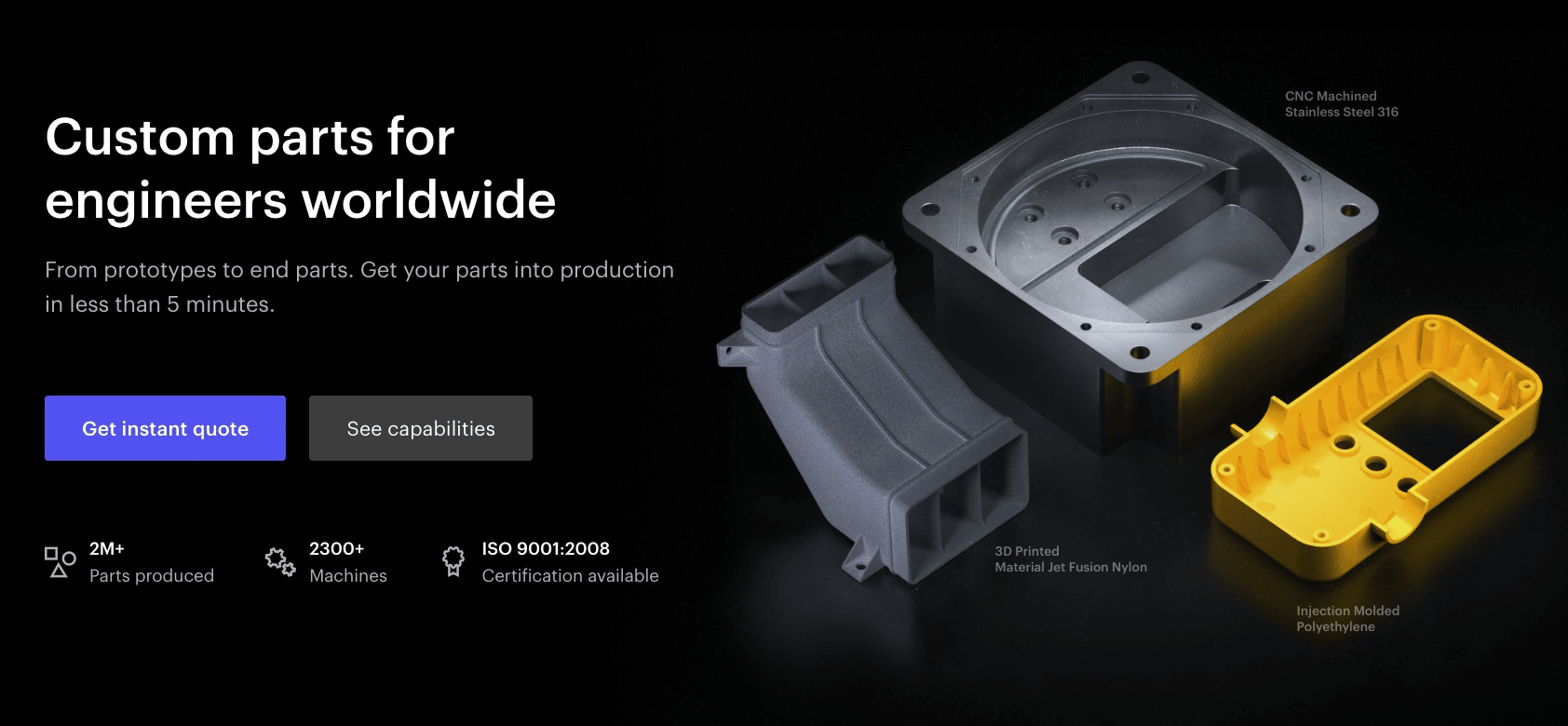

Getting a CNC machining quote is the first step in getting the job done. 3D Hubs offers the widest range of technologies and materials for CNC machining. From prototyping to full production runs. Benefit from 3D Hubs global network of certified CNC manufacturing facilities and get your parts into production in less than 5 minutes.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS