We love 3D printing here at Bit Rebels, and we’ve written about everything from 3D printed action figures to 3D printed body parts. The technology behind 3D printing just keeps getting better, and the applications seem to be endless. It continues to improve lives in many different ways. Today I’d like to share a 3D printed wrist splint that may someday be a way for people in underdeveloped regions or disaster zones to get immediate medical relief for their injuries.

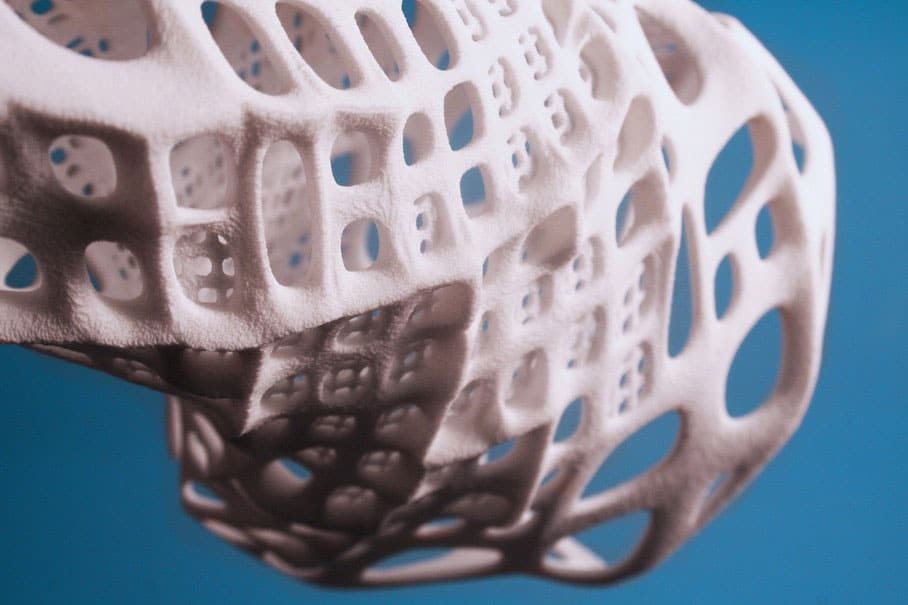

These wrist splints are intricate, detailed and customized for a perfect fit and optimal support. They were created by a few graduate students at UCLA’s school of Architecture & Urban Design. What you see below is a prototype exoskeleton, which was designed around the actual structure of the bone. They were inspired because of the need for them in underdeveloped regions around the world.

These 3D printed wrist splints are very strong, lightweight and cheap to make (once someone has the equipment that is). With a 3D scanner and a modifiable CAD file, each one could be custom made to fit perfectly.

I can imagine that in an underdeveloped region or disaster zone where these wrist splints might be in high demand, it would feel like a lifesaver to be able to just start printing them one after another. The whole process is so much more efficient in every way when compared to waiting for expensive, traditional treatment.

The 3D printing method used to create these is selective laser sintering or SLS. The only bummer part of this whole plan is that the SLS machines needed to make these a reality are large, expensive and require a lot of maintenance. As technology progresses, the cost will come down and the machines will most likely be much more portable. As fast as 3D printing technology is advancing, it’s not far-fetched to think that this would happen sooner rather than later. You can watch the video below to learn more.

Customized 3D Printed Wrist Splint

(Click Images To Enlarge)

Via: [Popsci]

COMMENTS